Home > News ( 2 )

H59 brass is a common copper-zinc alloy, the following is its detailed introduction: Chemical composition Copper (Cu) content of 57.0% to 60.0%, zinc (Zn) for the balance, in addition to lead (Pb) ≤ 0.5%, phosphorus (P) ≤ 0.01%, iron (Fe) ≤ 0.3%, antimony (S……

MORE+

Ensure sufficient lubricant volume Regularly check and maintain the oil pump: the oil pump is the key equipment to ensure the normal supply of lubricating oil. It is necessary to check the working condition of the oil pump regularly according to the instruct……

MORE+

Cone crusher copper sleeve burning sleeve mainly has the following reasons: First, lubrication Insufficient lubrication Lubricating oil pump failure: if the oil pump can not work normally, and can not deliver the lubricating oil to the copper bushing and oth……

MORE+

Appearance changes Discoloration: The surface color of copper bushing will change. Normal copper bushing is generally copper color, when burned, due to high temperature oxidation, the surface of copper bushing may become black, blue or dark brown. For exampl……

MORE+

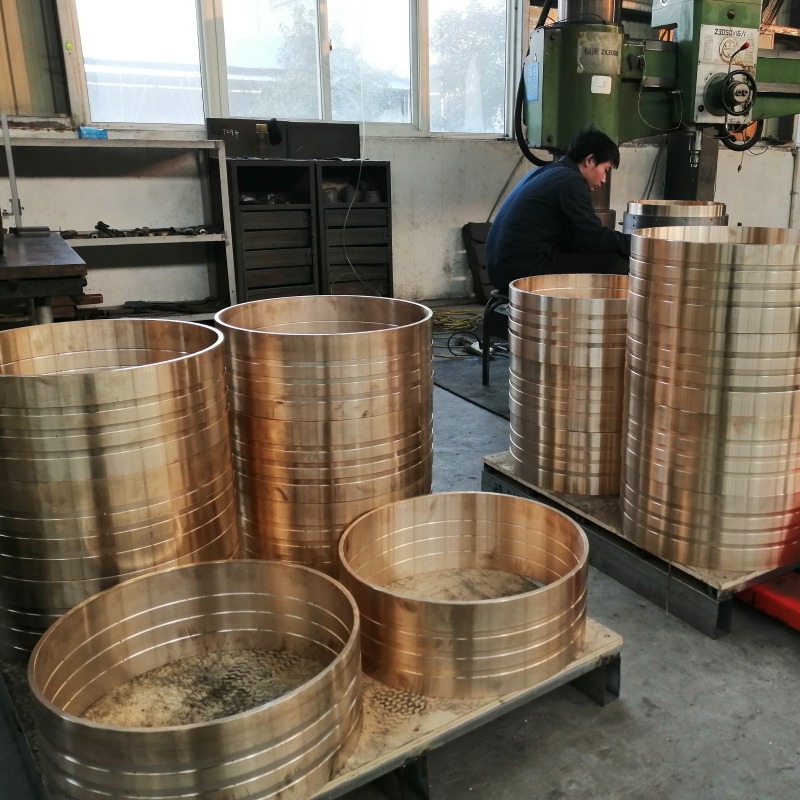

The following is a comparison of the wear resistance of copper bushings of several common materials: Tin bronze bronze bushings: Advantages: tin bronze with tin as the main alloying element, with high wear resistance. Its crystallization temperature range is……

MORE+

Decrease in equipment accuracy Copper bushings play a supporting and positioning role in many mechanical structures. For example, in the spindle system of the machine tool, broken copper bushing will make the spindle rotation accuracy affected. In the case o……

MORE+

Pulley shaft area The pulley block of a crane plays a key role in the lifting and luffing process. The installation of copper bushings on the pulley shaft can reduce the friction between the pulley shaft and the pulley seat. For example, in the hoisting pull……

MORE+

There are mainly the following types of copper bushing for cranes: Guide pulley copper bushing: installed in the crane guide pulley, play a role in reducing the friction between the pulley and the shaft, reduce wear and tear, to ensure that the pulley can ro……

MORE+

The repaired eccentric copper bushing may have some impact on the performance of the crusher as follows: 1.Aspects that may have a positive impact Restore normal operation of the equipment When the eccentric copper bushing is worn, if proper repair is carrie……

MORE+

Methods to improve hardness and wear resistance Selection of suitable material and heat treatment process: The hardness and wear resistance of copper bushing can be improved by selecting suitable copper alloy materials and adopting appropriate heat treatment……

MORE+

+86 17719955658

AddMazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

E-maildora@hsjxchina.com

Copyright @ 2025 Haishan Bronze Casting No:84463

Copyright @ 2025 Haishan Bronze Casting

Copyright @ 2025 Haishan Bronze Casting