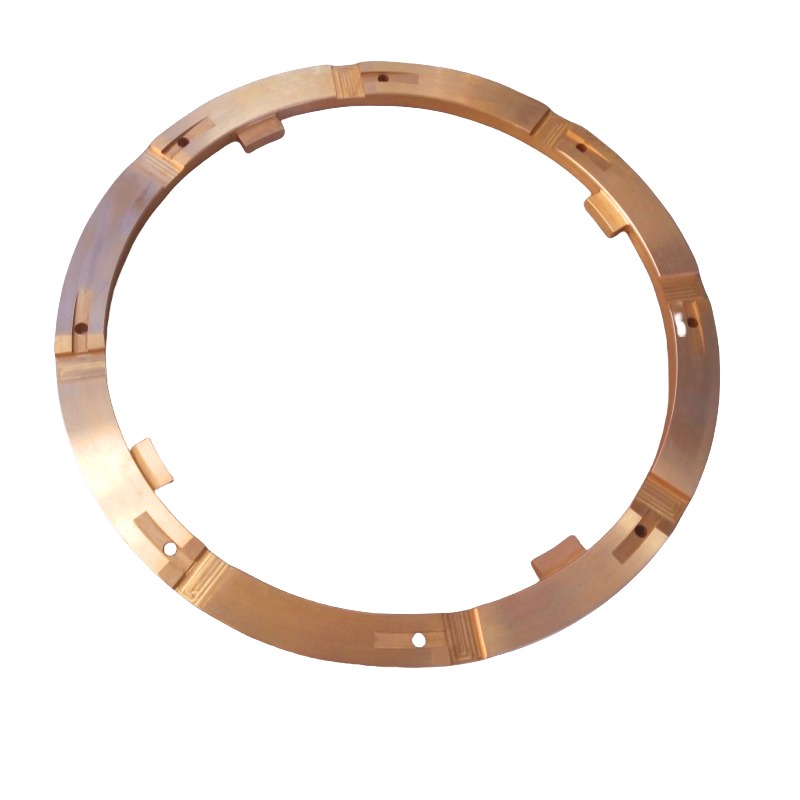

Applicable Scenarios: Split copper bushing: It is suitable for equipment that requires frequent replacement of copper bushing or maintenance, as well as occasions where the installation space is limited and the structure of the shaft is complicated. For exam……

MORE+

The lubrication intervals for the external copper bushing of a crusher depend on a number of factors, generally speaking, the approximate ranges are as follows: Crushers in continuous operation For crushers with high work intensity and harsh operating enviro……

MORE+

Tin bronze and aluminum bronze have their own characteristics, in the choice of which is more suitable for gears need to consider a combination of factors, the specific differences are as follows: Mechanical properties: Strength: Aluminum bronze: higher stre……

MORE+

The mechanical properties of graphite copper bushings include the following: Hardness: The hardness of graphite copper bushings of different base materials varies. For example, with high force brass as the substrate of graphite copper bushing, its hardness i……

MORE+

Replacement Precautions: When replacing different types of copper bushings, it is necessary to choose the appropriate replacement method according to the specific situation. For example, when replacing the eccentric sleeve copper bushing, it is necessary to ……

MORE+

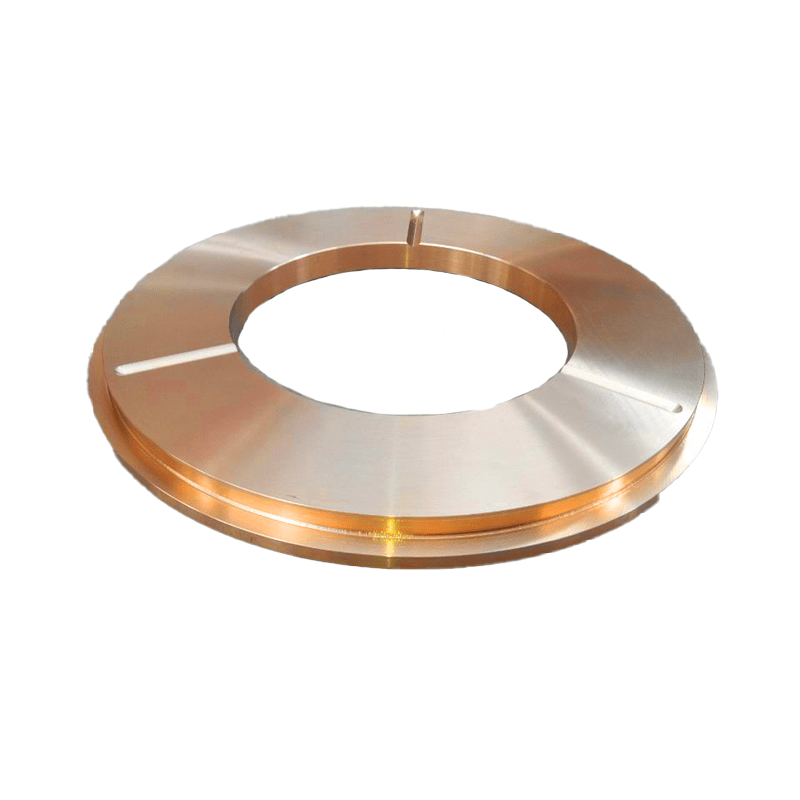

The machining process of flange copper bushing usually includes the following steps: Preparing raw materials: according to the design requirements of flange copper bushing, choose suitable copper materials, such as brass, tin bronze, etc. Casting: Heat the c……

MORE+

Copper bushing and flange with the accuracy of the equipment performance will have a variety of aspects of the impact, as follows: First, the sealing performance Prevent leakage: When the copper bushing and flange fit with high precision, the gap between the……

MORE+

Thrust bearing urns have the following serious effects on the normal operation of the crusher: First. Mechanical properties Reduced running accuracy: After burned thrust bearing, its rolling body, raceway and other parts will have deformation, wear and surfa……

MORE+

The main reasons for crusher thrust bearing burns are as follows: First. Poor lubrication Insufficient lubricant: The lubricant cannot be supplied to the thrust bearing normally, probably due to the failure of the lubrication system, such as damage of the oi……

MORE+

There are mainly the following types of thrust bearings for crushers: First. Sliding thrust bearings Plane thrust sliding bearing: It consists of thrust ring and several fan-shaped thrust tiles. The thrust ring is fixed on the shaft or sleeve, and the thrust……

MORE+

+86 17719955658

AddMazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

E-maildora@hsjxchina.com

Copyright @ 2025 Haishan Bronze Casting No:84463

Copyright @ 2025 Haishan Bronze Casting

Copyright @ 2025 Haishan Bronze Casting