Home > News > Industry news > How many types of thrust bearings are there in a crusher?

There are mainly the following types of thrust bearings for crushers:

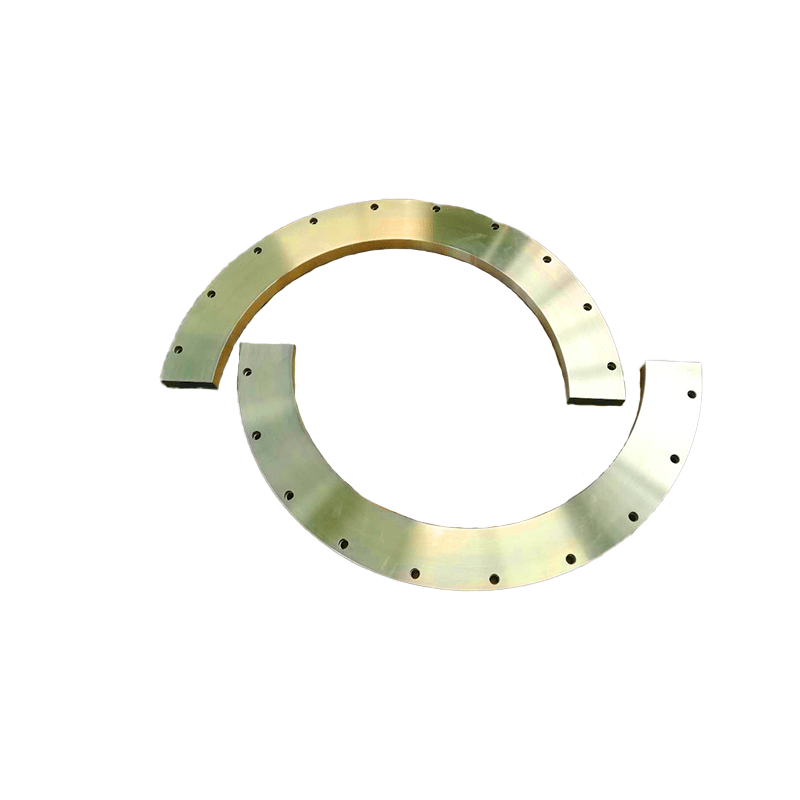

Plane thrust sliding bearing:

It consists of thrust ring and several fan-shaped thrust tiles. The thrust ring is fixed on the shaft or sleeve, and the thrust tile is installed in the bearing housing. When the shaft is subjected to axial force, the thrust ring transmits the force to the thrust tile, and an oil film is formed between the thrust tile and the bearing housing to withstand the axial force. This kind of bearing has simple structure and low cost, but the bearing capacity is relatively small, which is suitable for small and medium-sized crushers.

Tapered thrust plain bearing:

Its thrust surface is taper surface, which fits with the taper surface on the shaft. When the shaft is subjected to axial force, the force is transmitted to the bearing housing through the interaction of the tapered surface, forming an oil film to bear the axial force. The bearing capacity of taper thrust plain bearing is slightly larger than that of plane thrust plain bearing, and it has the function of automatic centering, which is suitable for some crushers with higher requirements on axial force.

Thrust ball bearings:

By the shaft circle, seat ring, steel ball and keep frame composition. The shaft ring is mounted on the shaft, and the seat ring is mounted in the bearing housing. When the shaft is subjected to axial force, the steel ball rolling between the shaft circle and seat ring, bear axial force.

The bearing capacity of thrust ball bearing is relatively small, but the rotational speed is high, which is suitable for small crusher or occasions requiring high rotational speed.

Thrust roller bearings:

Including thrust cylindrical roller bearings, thrust tapered roller bearings and thrust spherical roller bearings.

Thrust cylindrical roller bearings are composed of shaft ring, seat ring, cylindrical roller and cage, the bearing capacity is larger than the thrust ball bearings, suitable for medium axial force crusher. Thrust tapered roller bearings have tapered rollers with higher load carrying capacity and automatic self-aligning function, which are suitable for crushers with larger axial force and certain installation error. Spherical roller thrust bearings can withstand large axial force and radial force, and at the same time has the automatic centering function, suitable for complex working conditions of the crusher.

Working principle:

Through the external oil supply system will have a certain pressure of lubricating oil into the oil cavity of the bearing, the formation of hydrostatic oil film, so as to withstand the axial force.

Characteristics: large bearing capacity, small friction coefficient, suitable for large crusher or higher precision requirements of the occasion. However, it needs to be equipped with a specialized oil supply system, which is costly and relatively complicated to maintain.

+86 17719955658

AddMazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

E-maildora@hsjxchina.com

Copyright @ 2025 Haishan Bronze Casting No:84463

Copyright @ 2025 Haishan Bronze Casting

Copyright @ 2025 Haishan Bronze Casting