Home > News > Industry news > Which has better wear resistance, self-lubricating copper bushings or graphite copper bushings?

Generally graphite copper bushings have relatively better wear resistance for the following reasons:

Graphite copper bushing: During the sliding friction between the shaft and the bearing, a part of the graphite particles will be transferred to the friction surface of the shaft and the bearing, forming a layer of more stable solid lubrication diaphragm. This diaphragm can effectively prevent the direct adhesive wear of the shaft and bearing, which greatly reduces the friction coefficient and lowers the degree of wear. Even in the process of long-time use, graphite particles can continue to provide lubrication, to ensure the wear resistance of the copper bushing.

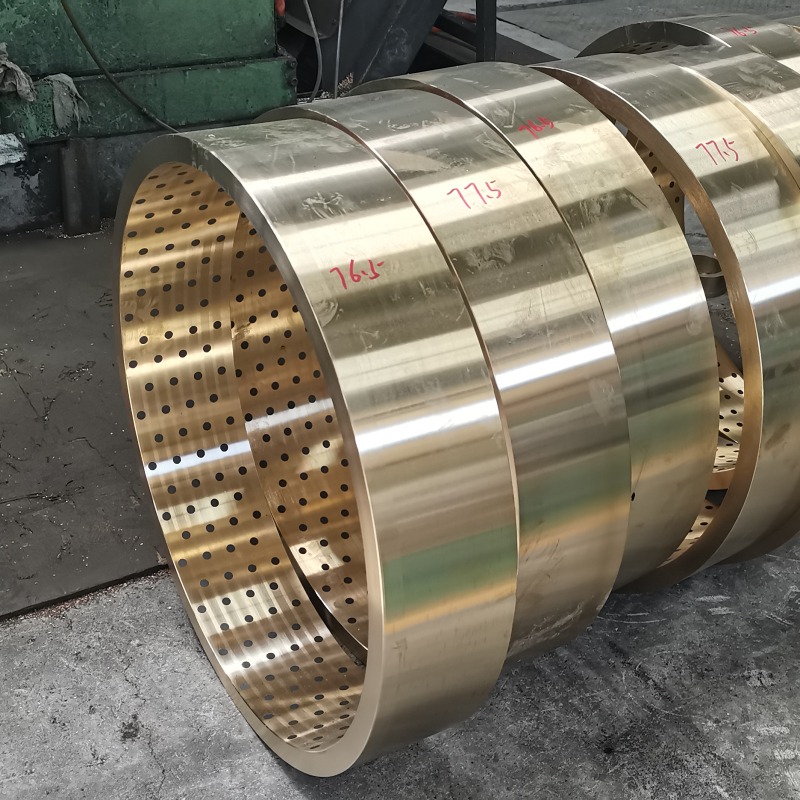

Self-lubricating copper bushing: Usually, holes are machined and filled with solid lubricant (e.g. PTFE, etc.) on the copper bushing substrate. In the friction process, the solid lubricant will gradually ooze out to play a lubricating effect. However, with the increase of the use of time, the solid lubricant may be consumed, uneven distribution and so on, resulting in a decline in the lubrication effect, which in turn affects its wear resistance.

Characteristics of graphite: graphite itself has high hardness and good chemical stability, in the friction process is not easy to deformation and chemical reaction. Its hardness can withstand greater pressure and friction, reducing material loss due to surface abrasion.7 At the same time, the structure of graphite gives it good self-lubricating properties, enabling the formation of a smooth lubrication layer on the friction surface, which further reduces wear.

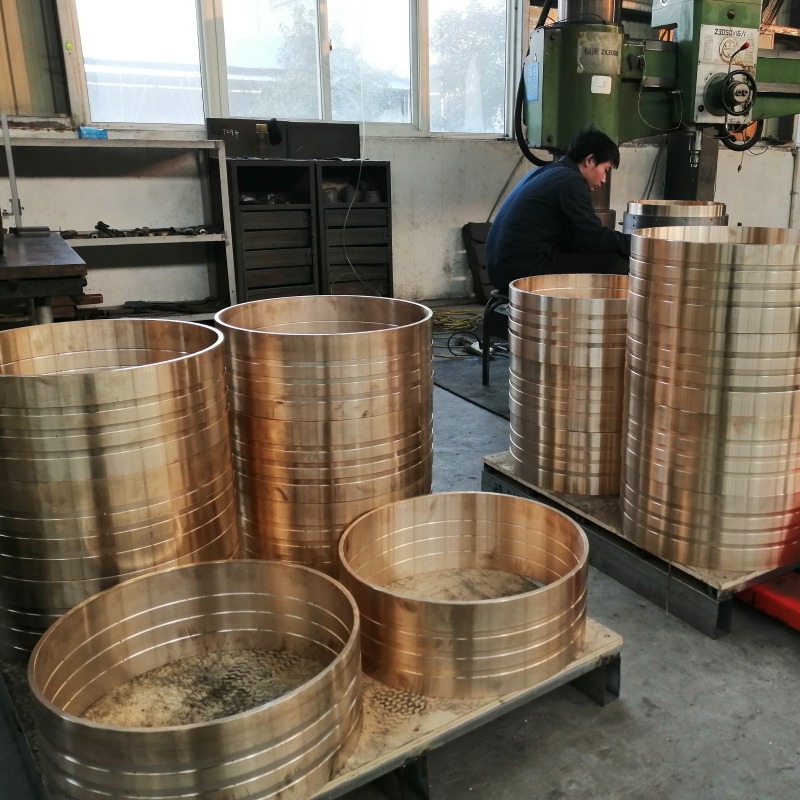

Comparison of copper bushing substrates: most of the substrates of self-lubricating copper bushing and graphite copper bushing are copper alloys. Although the copper alloy itself has a certain degree of wear resistance, but in a long time in the friction process, there will be wear phenomenon. The graphite in the graphite bushing can effectively share the friction pressure and reduce the wear of the copper matrix, thus improving the wear resistance of the whole bushing.

Graphite copper bushing: with high bearing capacity, impact resistance, high temperature resistance and other characteristics, especially suitable for heavy load, low speed, reciprocating or oscillating and other difficult to lubricate and form an oil film occasions, such as metallurgical continuous casting machine, rolling equipment, mining machinery, etc. 11. In these harsh working conditions, graphite copper bushing wear resistance advantage is more obvious.

Self-lubricating copper bushing: mainly used for low speed, high load bearing occasions, but in some extremely harsh working conditions, its wear resistance may not be compared with graphite copper bushing.

+86 17719955658

AddMazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

E-maildora@hsjxchina.com

Copyright @ 2025 Haishan Bronze Casting No:84463

Copyright @ 2025 Haishan Bronze Casting

Copyright @ 2025 Haishan Bronze Casting