Home > News > Industry news > What are the differences between metal casting and centrifugal casting in the production of copper fittings?

There are significant differences between metal casting and centrifugal casting in the production of copper fittings.

High density and denseness: centrifugal force makes the molten metal fit closely to the inner wall of the mould, copper fittings have high density, dense internal tissue, no air holes or inclusions.

High material utilisation: less material waste and high metal utilisation due to no complex gating system.

Better surface quality: Since the metal is in contact with the mould under high pressure, the surface quality of copper fittings is usually better.

High density and denseness: centrifugal force makes the molten metal closely fit the inner wall of the mould, copper fittings have high density and dense internal tissue without air holes or inclusions.

High material utilisation: As no complex gating system is required, there is less material wastage and high metal utilisation.

Better surface quality: As the metal is in contact with the mould under high pressure, the surface quality of copper fittings is usually better.

Higher efficiency: it is suitable for mass production, especially for parts with regular shape, such as tubular or round parts, and the production speed is fast.

Higher mould costs: Centrifugal casting equipment and moulds are more costly, but the cost is diluted in mass production.

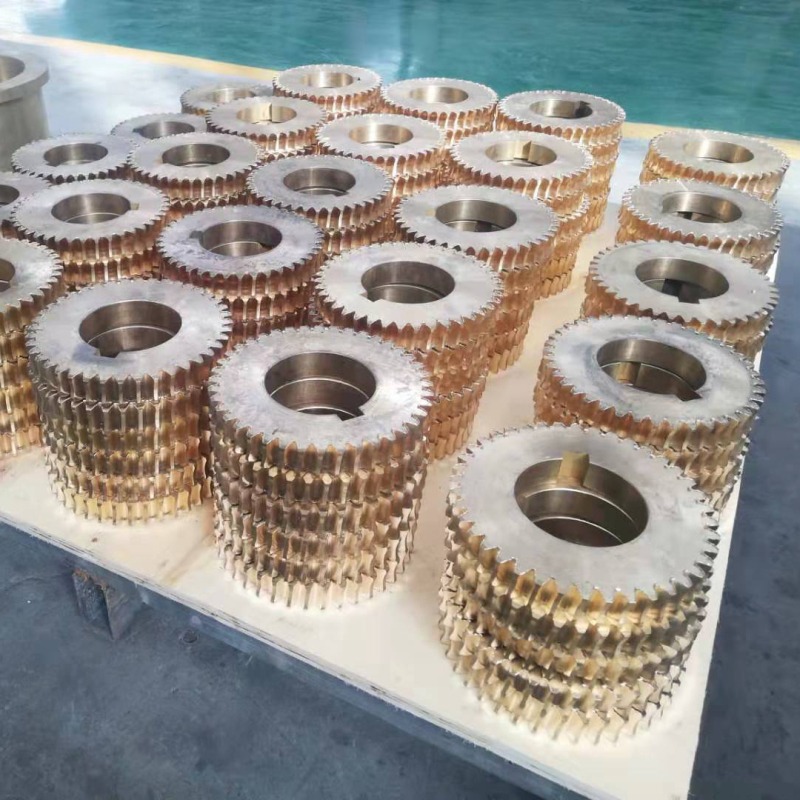

Suitable for hollow, round and symmetrical copper parts, such as copper bushings, copper tubes, copper rings and copper sleeves. Particularly suitable for copper fittings requiring high strength and density.

Gravity casting: the molten metal is poured into the mould by gravity and relies on gravity flow to fill the mould cavity.

Suitable for complex shapes of copper fittings: capable of producing copper fittings of all shapes and sizes, including complex geometries.

Complex gating systems: the design and manufacture of gating and riser systems is required to ensure that the metal fills the mould smoothly and that gases and impurities are removed.

Possibility of defects: Gravity can lead to defects such as porosity, shrinkage and inclusions, especially in complex copper fittings.

Lower material utilisation: The design of systems such as gates and risers can lead to greater material wastage and lower metal utilisation.

Surface quality depends on the process: the surface roughness of sand casting is larger, while the surface quality of precision casting is higher.

Suitable for a variety of production scales: can be used for small or large batch production, high flexibility, mould costs depending on the process.

Longer production cycle: especially for sand casting, longer mould manufacturing and preparation time, longer casting cycle for complex copper fittings.

Suitable for copper fittings with complex shapes and diverse sizes, such as pump shells, valve bodies, brackets and connectors. Suitable for copper fittings with high requirements for surface quality or complex geometry.

+86 17719955658

AddMazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

E-maildora@hsjxchina.com

Copyright @ 2025 Haishan Bronze Casting No:84463

Copyright @ 2025 Haishan Bronze Casting

Copyright @ 2025 Haishan Bronze Casting