Our strength

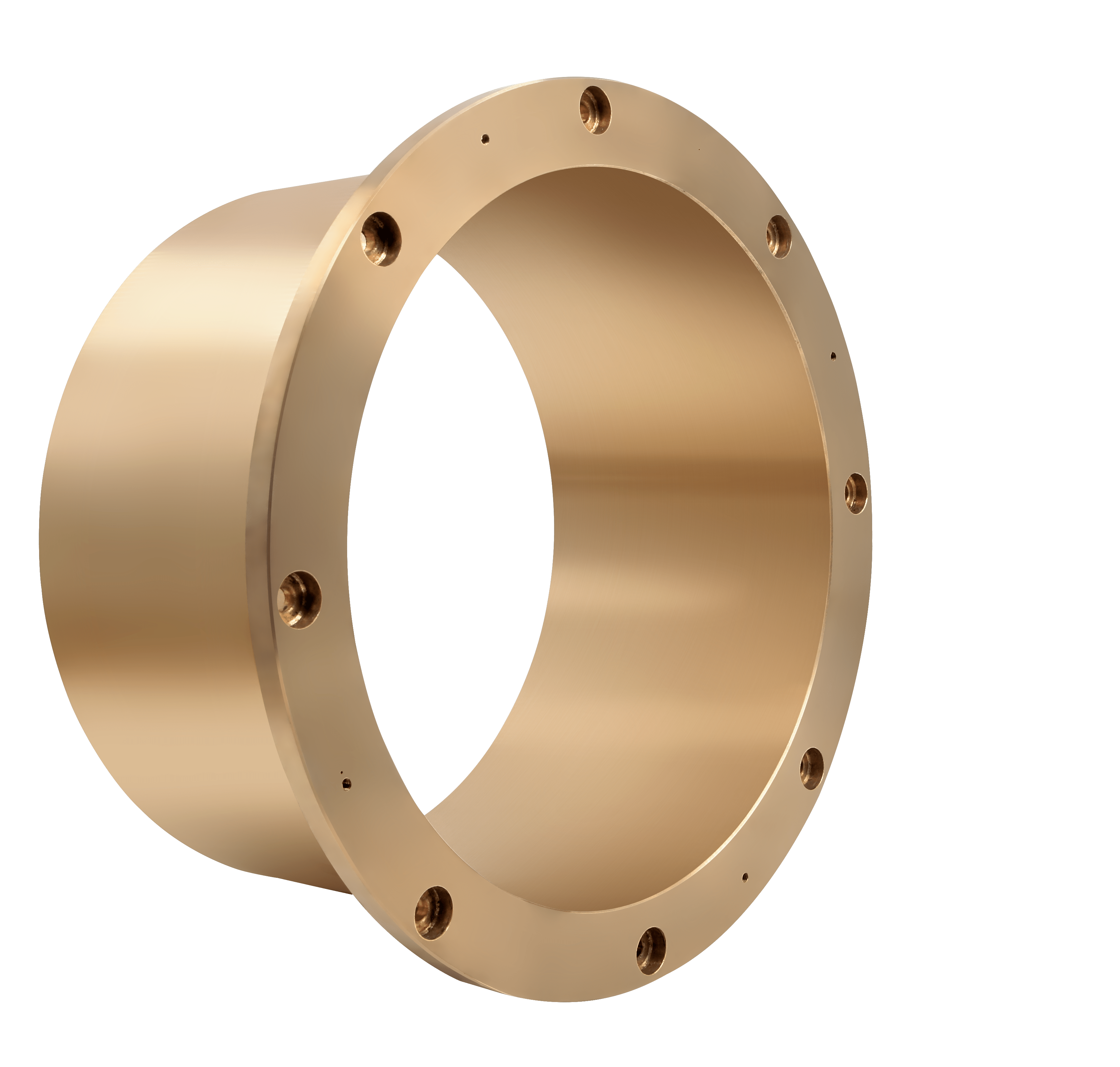

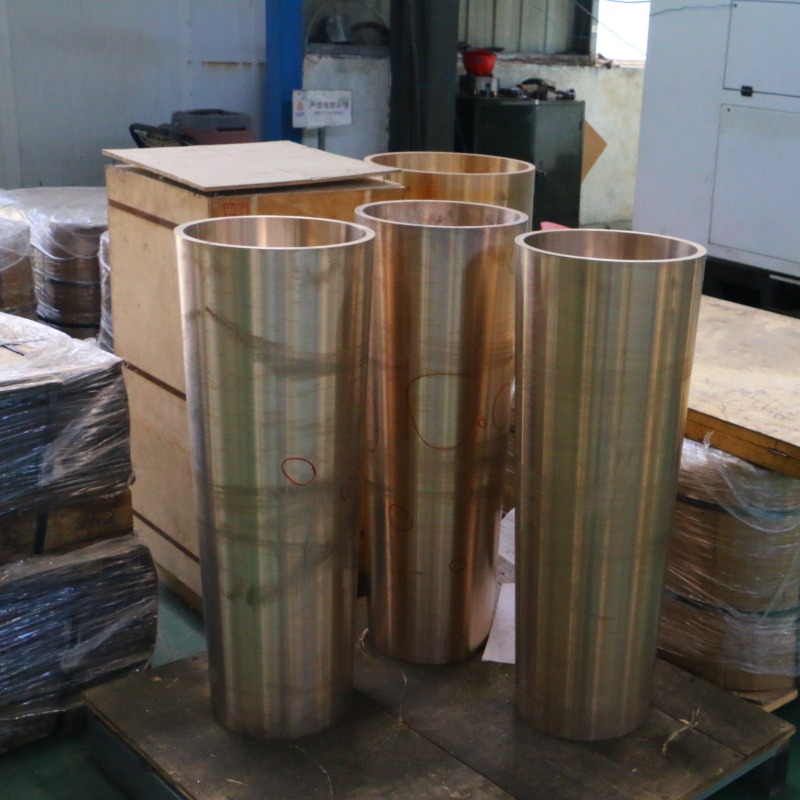

Xinxiang Haishan Machinery Co., Ltd. has been focusing on one-stop supply chain services for wear-resistant copper sleeves for more than 20 years, and can provide one-stop services from product research and development, production, processing, technical consultants, sales and independent brands.

Experienced: The core members have 10-15 years of manufacturing experience in the copper casting industry, and the team’s operating efficiency has increased by 30%. Adopting international design concepts, the equipment operating efficiency is 99.9%, which can save you 30% of operating costs.

Strong technical team: It has a 20-person R&D team and a number of patented technologies for copper casting production and processing; 4 senior engineers for copper casting production and processing equipment, and they have successfully implemented dozens of copper casting production and processing projects.

Production safety: The copper castings provided can track the production progress, quality control, quality inspection, delivery and other links of each batch of products in real time, which can reduce costs, increase efficiency and ensure the construction period.

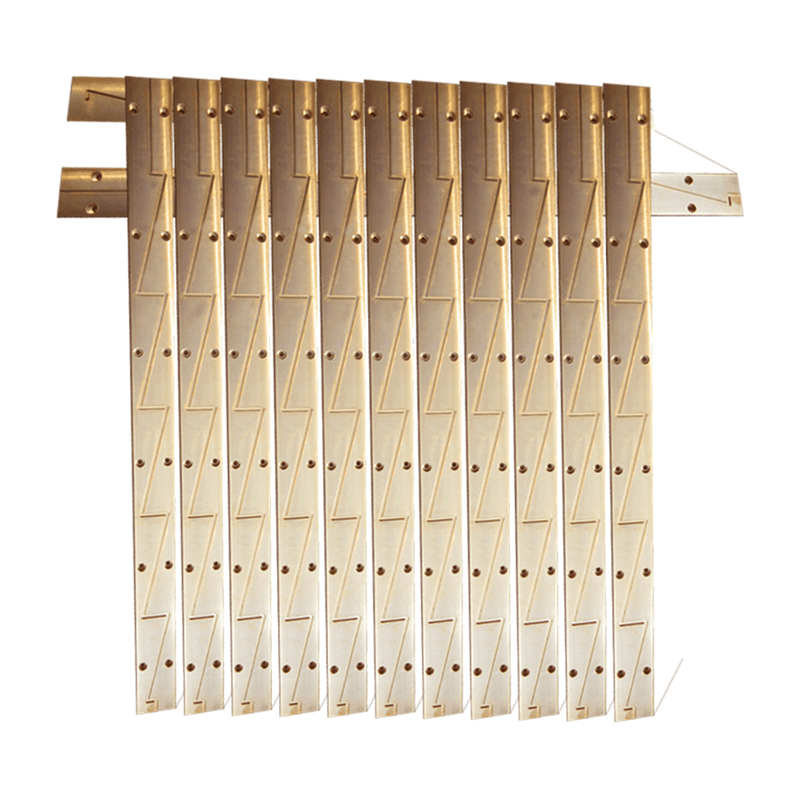

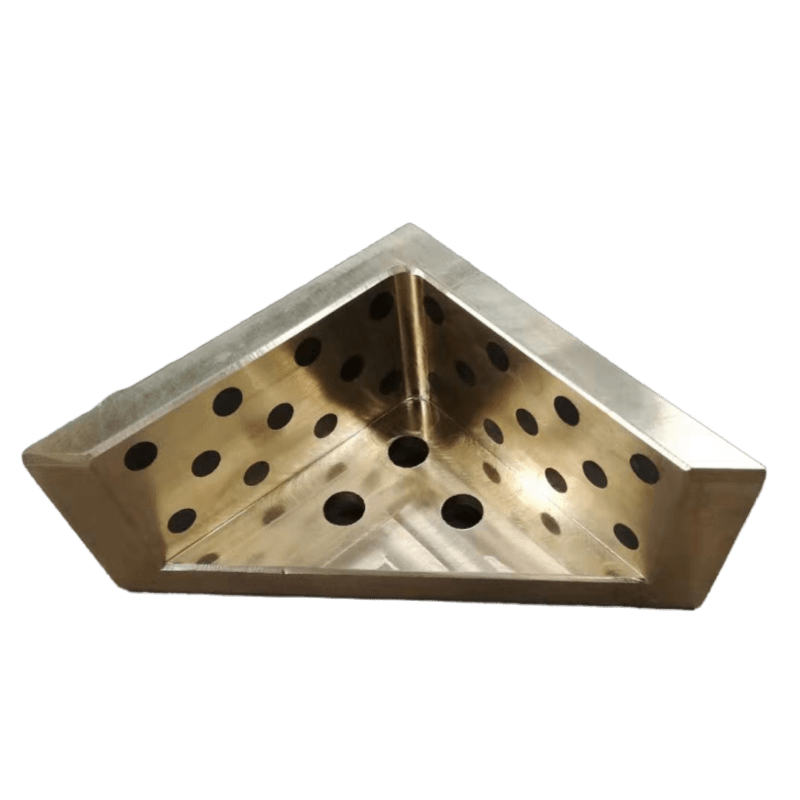

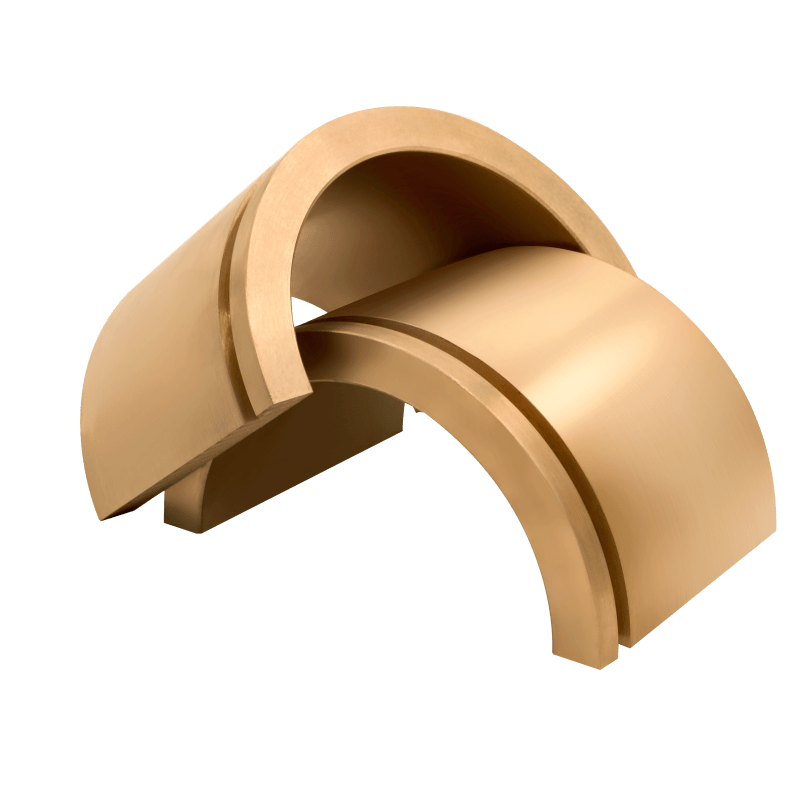

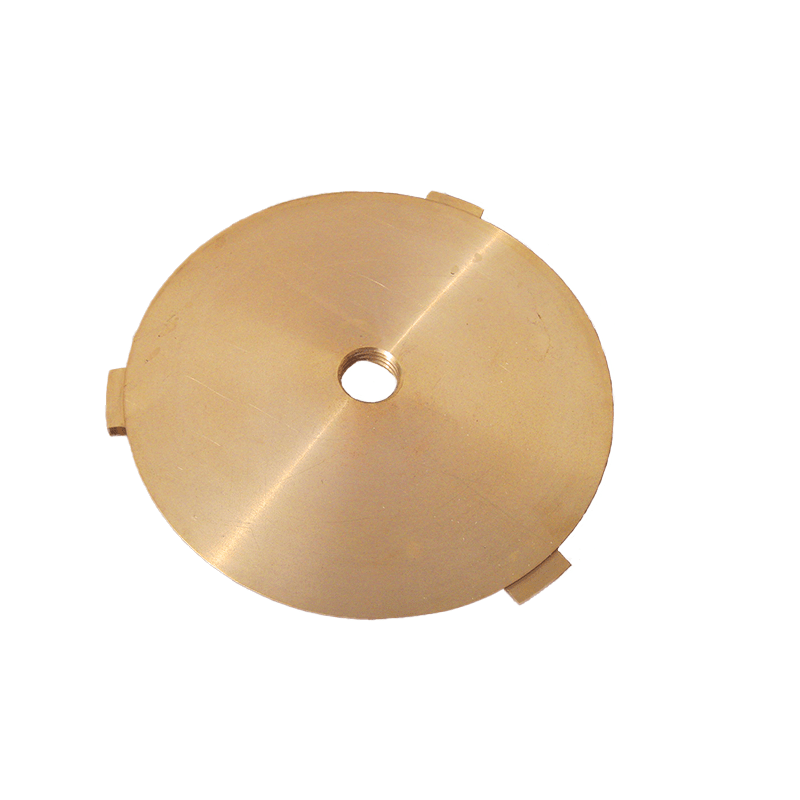

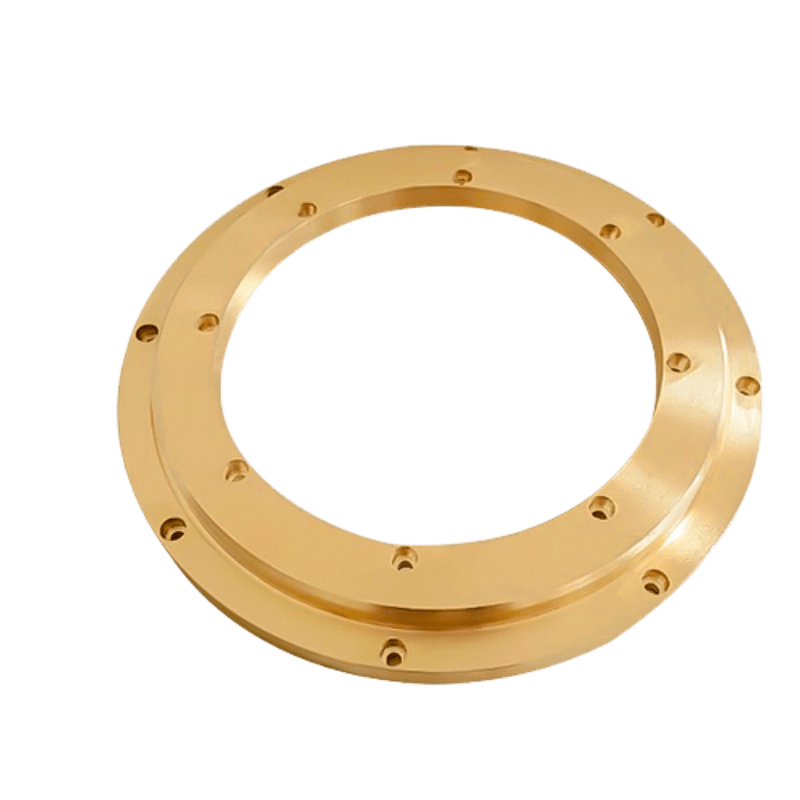

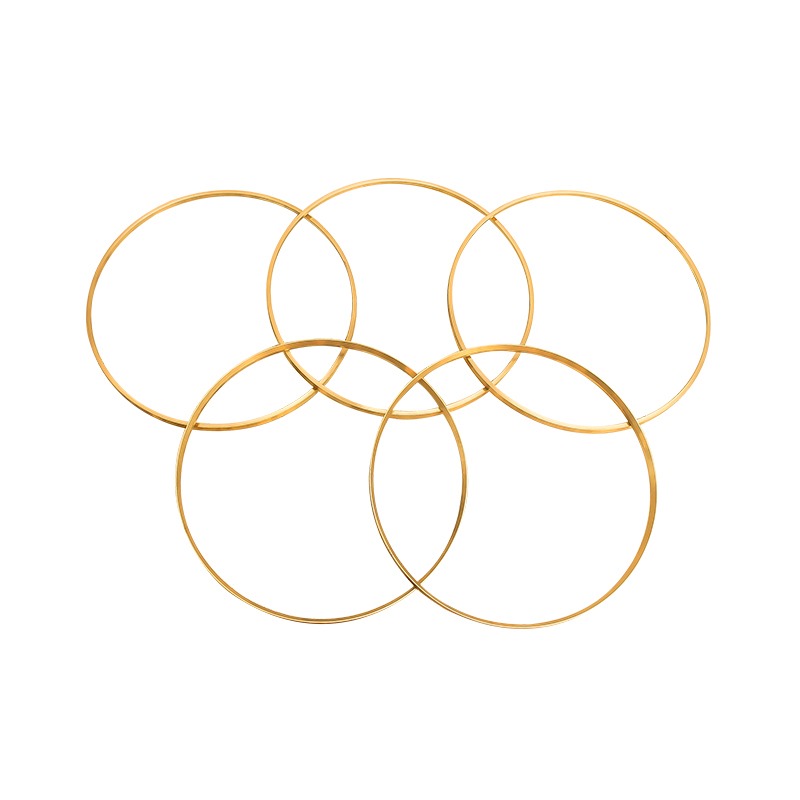

About UsPopular products

It specializes in providing one-stop services for R & D, production

and sales of agricultural equipment

News

It specializes in providing one-stop services for R & D, production

and sales of agricultural equipment

-

Release time:2024-12-06

Can graphite copper bushing be used in tip rolling machines?

Graphite copper bushing can be used in tip rolling machines. Lubrication performance Graphite copper bushing has self-lubricating property. During the working process of the tip rolling machine, the…… -

Release time:2024-12-05

How to test the wear resistance of copper bushings?

Hardness Test Aids Evaluation Brinell hardness test: Using a carbide ball of a certain diameter, under a specified load and time, it is pressed into the surface of a copper bushing and the diameter …… -

Release time:2024-12-04

Brass is a copper-zinc alloy so why would a magnet suck it?

Reasons for impurities Brass is an alloy of copper and zinc, but may contain small amounts of iron impurities during the actual production process. These iron impurities may come from raw materials,……