Home > News > Industry news > How to increase the lubrication of copper sleeve?

Increasing the lubricity of copper sleeves can be optimized in terms of materials, structural design, surface treatment and external lubrication methods. The following are some specific measures:

Use of self-lubricating materials

Self-lubricating copper alloy: the use of copper alloy containing solid lubricants (such as graphite, molybdenum disulfide, etc.) can form a solid lubrication film on the contact surface of thecopper sleeve and shaft. These solid lubricants are effective in reducing friction and increasing the lubricity of the copper sleeve, and are especially good in environments where liquid lubrication is not readily available.

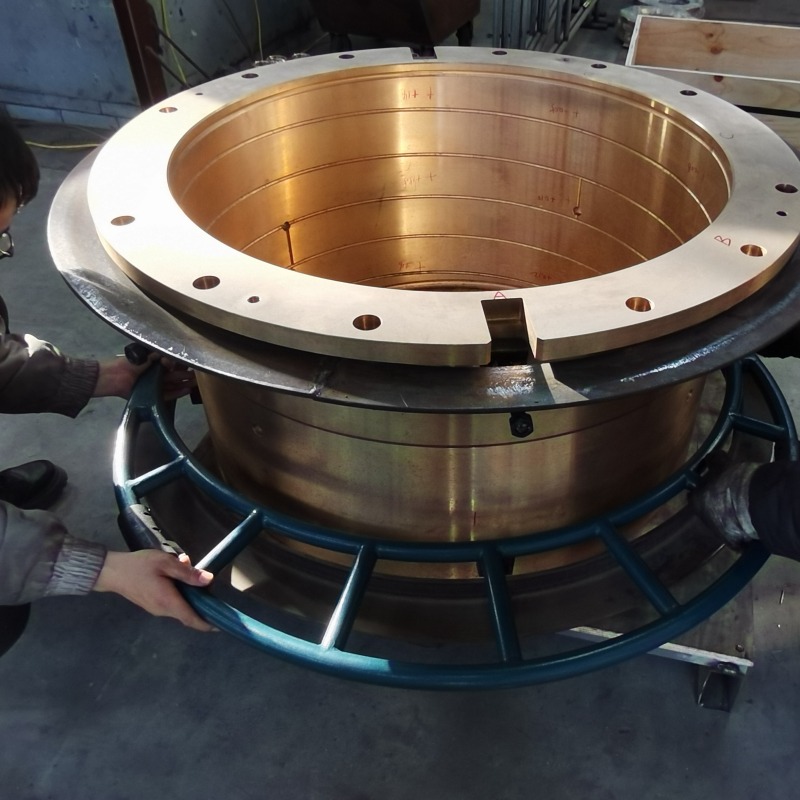

Adding lubrication grooves or holes

Designing grooves or holes: Spiral or circular grooves, or holes, are machined into the surface of the bushing to store lubricant and automatically release it to the friction surfaces during operation, ensuring continuous lubrication. This design is particularly suitable for high-speed, heavy-duty applications.

Distribution of holes and grooves: According to the load direction of the copper sleeve and the contact condition of the friction surface, the location of oil grooves and oil holes are reasonably distributed to ensure that the lubricant can effectively cover the entire contact area.

Enhance the surface finish of copper sleeve

Finishing: Through polishing, grinding and other finishing means, reduce the roughness of the surface of the copper sleeves, reduce the coefficient of friction. A smooth surface reduces the frictional resistance with the shaft, thus improving the lubrication effect.

Use high quality lubricant or grease

Choose efficient lubricants: Use high temperature oxidation-resistant, wear-resistant lubricants or greases that can maintain good lubrication under high loads and extreme environments. For some special-purpose copper sleeve, specially formulated lubricants can provide better results.

Regular lubrication: Use automatic lubrication system or add lubricant manually at regular intervals to ensure that the lubricant can be supplied in time to avoid dry friction and wear of copper sleeve due to lack of oil.

Adoption of oil impregnation process

Impregnation with lubricating oil: The copper sleeve is impregnated with lubricating oil so that it absorbs a certain amount of lubricating oil, especially for porous copper alloys. This impregnation process enables the copper sleeve to release lubricant slowly during the working process and ensures long-term lubrication effect.

Optimized structure design

Optimize the clearance between shaft and copper sleeve: reasonable clearance between shaft and copper sleeve helps lubricant circulation, too small a clearance will lead to insufficient lubricant, while too large will lead to the loss of lubricant, making it difficult to form an effective lubrication film.

Reduce the contact area: appropriate to reduce the direct contact area between the copper sleeve and the shaft, can increase the thickness of the oil film, reduce friction.

Through the above methods, the lubrication of the copper sleeve can be significantly improved, not only to reduce friction and wear, but also to extend the service life of the equipment and improve work efficiency.

+86 17719955658

AddMazhuang Village, Yuhe Town, Huixian City, Xinxiang City, Henan Province, China

E-maildora@hsjxchina.com

Copyright @ 2024 Haishan Bronze Casting No:84463

Copyright @ 2024 Haishan Bronze Casting

Copyright @ 2024 Haishan Bronze Casting